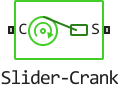

Slider-Crank

Crank-slider mechanism.

blockType: AcausalFoundation.Mechanical.Mechanisms.SliderCrank

|

Path in the library: |

Description

Block Slider-Crank It is a crank-slider mechanism as a converter between the continuous rotational movement of the crank and the reciprocating movement of the slider.

The mechanism has two connections:

-

Port C corresponds to a crank and represents a rotary mechanical port.

-

Port S corresponds to a slider and represents a translational mechanical port.

The parameters Crank radius and Rod length describe the geometry of the mechanism. The inertia of the crank, set by the Crank inertia parameter, is necessary to pass the upper and lower dead points when the connecting rod is exactly in the center of the crank.

Taking into account the stiffness and mechanism and the damping coefficient set by the parameters Slider stiffness and Slider damping is necessary to reduce the inertial coupling between the ports; too tight coupling can cause computational problems. The unit provides rigidity and damping between the ideal position of the slider (calculated based on geometry) and the actual position of the mechanical translational port S. This correspondence avoids direct non-linear communication between ports. Higher rigidity leads to the fact that the movement approaches the ideal, but increases the computational rigidity of the system. Damping helps to smooth out the oscillations that can be caused by such rigidity of the system.

Ports

C — crank

rotational mechanics

Mechanical rotary port, corresponds to the crank.

S — pass slider:q[<br>] translational mechanics

Mechanical translational port, corresponds to the slider.

Parameters

Crank radius, m — the radius of the crank

0.1 m (by default)

The radius of the crank. The parameter value must be greater than zero.

Rod length, m — connecting rod length

0.2m (by default)

The length of the connecting rod connecting the crank and the slider. The parameter value must be greater than Crank radius.

Crank inertia, kg*m2 — moment of inertia of the crank

0.01 kg*m2 (by default)

The moment of inertia of the crank, necessary to pass the upper and lower dead points when the connecting rod is exactly in the center of the crank. The parameter value must be greater than zero.

Slider stiffness, N/m — stiffness of the position of the slider

1e6 N/m (by default)

Together with Slider damping provides a malleability that helps reduce inertial coupling between ports. Higher rigidity leads to the fact that the movement approaches the ideal, but increases the rigidity of the system. The parameter value must be greater than zero.

Slider damping, N/(m/s) — damping coefficient of the pass slider:q[<br>] 1e3 N/(m/s) (by default)

Together with the Slider stiffness, pliability is provided, which helps to reduce the inertial connection between the holes. Higher damping values smooth out the oscillation that can be caused by stiffness. The parameter value must be greater than zero.

Initial value of crank angle, rad — initial value of crank angle

0.0 (by default)

The initial value of the crank rotation angle.

Initial value of crank velocity, rad/s — initial value of crank velocity

0.0 (by default)

The initial value of the crank speed.