Specific Dissipation Heat Exchanger (TL-TL)

A heat exchanger parameterized based on data on the relative magnitude of heat transfer for systems with two streams of heat-conducting liquid.

blockType: EngeeFluids.HeatExchangers.SpecificDissipation.ThermalLiquidThermalLiquid

Path in the library: |

Description

Block Specific Dissipation Heat Exchanger (TL-TL) simulates additional cooling and heating of heat carriers in short-term thermal contact through a thin conductive wall. The block uses a simplified model based on the concept of the relative magnitude of heat transfer, which is a measure of the rate of heat transfer.

The heat transfer model

The heat transfer model of the unit depends on the heat transfer rate, determined by the relative magnitude of the heat transfer. The relative magnitude of heat transfer is a measure of the rate of heat transfer observed when the temperature difference between the heat—conducting liquid 1 and the heat-conducting liquid 2 at the inlet is one degree. Multiplying by the temperature difference at the inlet gives the expected heat transfer rate.:

where — relative magnitude of heat transfer, — temperature of the heat-conducting liquid 1 (lower index ) or heat - conducting liquid 2 (lower index ) at the entrance. The relative heat transfer value is a tabular function of the mass flow rate entering the heat exchanger through ports connected to heat-conducting fluids 1 and 2:

To account for reverse flows, the tabular data can be expanded for positive and negative flow rates, in which case the input ports can also be considered as output ports. The data is usually obtained by measuring the dependence of the heat transfer rate on the temperature in a real model.:

The heat transfer model, based almost entirely on tabular data, which is usually obtained experimentally, does not require a detailed description of the heat exchanger. It is assumed that the flow pattern of the heat carriers, the mixing condition and the number of strokes of the casing or pipe, if they are related to the simulated heat exchanger, are fully reflected in the tabular data.

For more information about heat transfer calculations, see the section Specific Dissipation Heat Transfer.

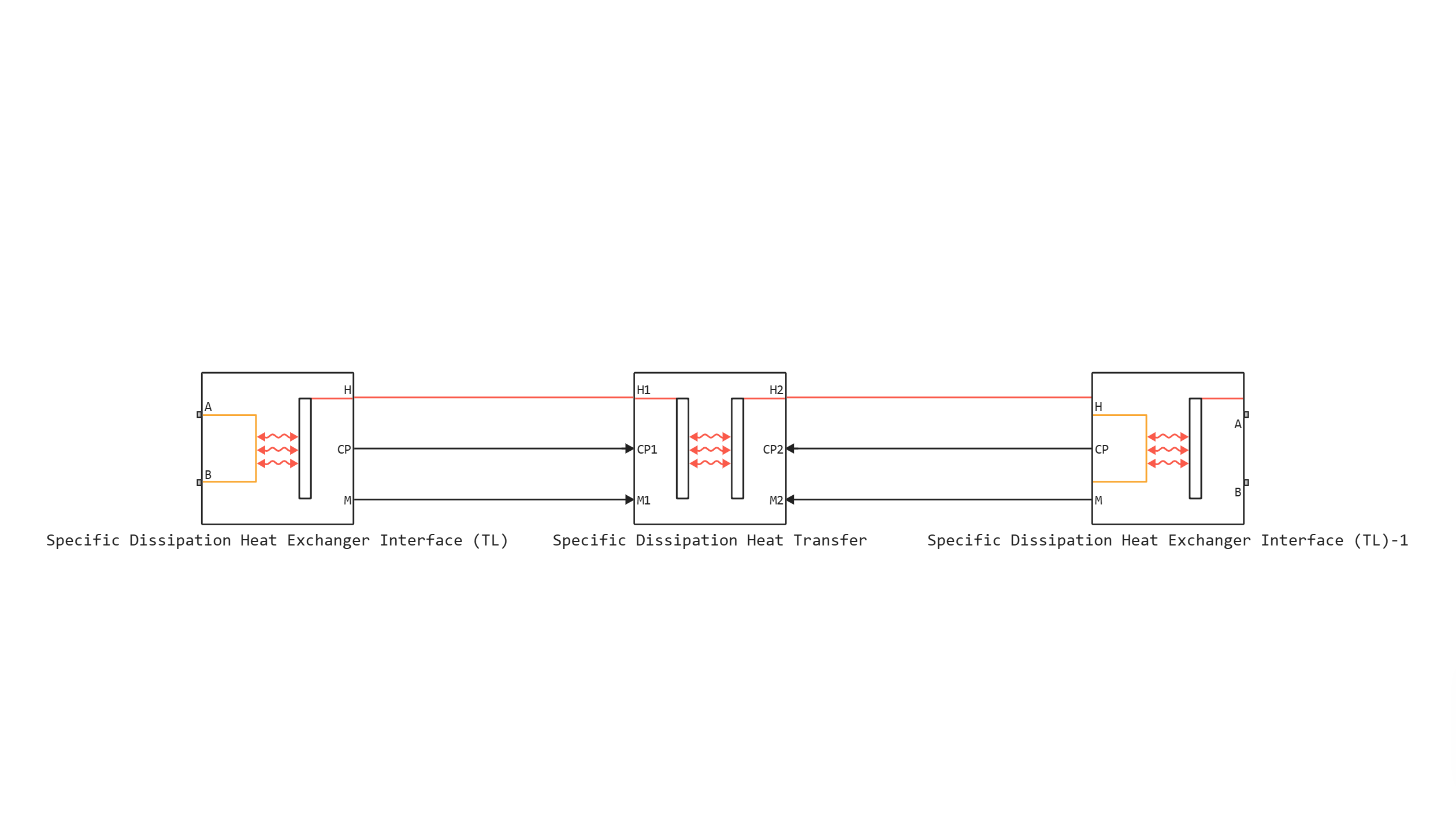

Block structure

A block is a composite component built from simpler blocks. Block Specific Dissipation Heat Exchanger Interface (TL) simulates the flow of heat-conducting liquid on side 1 of the heat exchanger. The other block simulates the flow of a heat-conducting liquid on side 2. Block Specific Dissipation Heat Transfer it takes into account the heat exchange between the flows through the wall.

Ports

Conserving

#

A1

—

inlet or outlet of the thermal liquid 1

thermal liquid

Details

The inlet or outlet port for the thermal liquid is 1 on the corresponding side of the heat exchanger.

| Program usage name |

|

#

B1

—

inlet or outlet of the thermal liquid 1

thermal liquid

Details

The inlet or outlet port for the thermal liquid is 1 on the corresponding side of the heat exchanger.

| Program usage name |

|

#

A2

—

inlet or outlet of the thermal liquid 2

thermal liquid

Details

The inlet or outlet port for the thermal liquid is 2 on the corresponding side of the heat exchanger.

| Program usage name |

|

#

B2

—

inlet or outlet of the thermal liquid 2

thermal liquid

Details

The inlet or outlet port for the thermal liquid is 2 on the corresponding side of the heat exchanger.

| Program usage name |

|

Parameters

Heat Transfer

#

Thermal Liquid 1 mass flow rate vector, mdot1 —

the mass flow rate of the heat-conducting liquid 1 at each break point in the interpolation table for the relative heat transfer value table

kg/s | kg/hr | kg/min | g/hr | g/min | g/s | t/hr | lbm/hr | lbm/min | lbm/s

Details

The mass flow rate of the heat-conducting liquid is 1 at each break point in the interpolation table for the relative heat transfer value table. The unit interpolates and extrapolates the values of the break points to obtain the relative heat transfer value of the heat exchanger at any mass flow rate.

The mass flow values can be positive, zero, or negative, but they must monotonously increase from left to right. Their number should be equal to the number of columns in the parameter. Specific dissipation table, SD(mdot1, mdot2). If the table contains lines and columns, then the vector of mass flow values has a length of elements.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Thermal Liquid 2 mass flow rate vector, mdot2 —

the mass flow rate of the heat-conducting liquid 2 at each break point in the interpolation table for the relative heat transfer value table

kg/s | kg/hr | kg/min | g/hr | g/min | g/s | t/hr | lbm/hr | lbm/min | lbm/s

Details

The mass flow rate of the heat-conducting liquid 2 at each break point in the interpolation table for the relative heat transfer value table. The unit interpolates and extrapolates the values of the break points to obtain the relative heat transfer value of the heat exchanger at any mass flow rate.

The mass flow values can be positive, zero, or negative, but they must monotonously increase from left to right. Their number should be equal to the number of columns in the parameter. Specific dissipation table, SD(mdot1, mdot2). If the table contains lines and columns, then the vector of mass flow values has a length of elements.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Specific dissipation table, SD(mdot1, mdot2) —

the relative value of heat transfer at each break point in the interpolation table of the mass flow rates of the heat-conducting liquid 1 and heat-conducting liquid 2

W/K | kW/K

Details

The relative value of heat transfer at each break point in the interpolation table of the mass flow rates of the heat-conducting liquid 1 and heat-conducting liquid 2. The unit interpolates and extrapolates the values of the break points to obtain efficiency for any pair of mass flow rates of the heat-conducting liquid 1 and heat-conducting liquid 2.

The values of the relative heat transfer value should not be negative. They should be aligned from top to bottom in the order of increasing mass flow in the channel for heat-conducting liquid 1 and from left to right in the order of increasing mass flow in the channel for heat-conducting liquid 2. The number of rows should be equal to the size of the parameter Thermal Liquid 1 mass flow rate vector, mdot1, and the number of columns corresponds to the size of the parameter Thermal Liquid 2 mass flow rate vector, mdot2.

If the heat transfer coefficients are specified in the technical data sheet of your heat exchanger, multiply them by the surface area to calculate the relative amount of heat transfer.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Check if violating maximum specific dissipation —

the status of the warning about the relative heat transfer value exceeding the minimum flow heat capacity

None | Error

Details

A warning about the relative heat transfer value exceeding the minimum flow heat capacity. The flow heat capacity is the product of the mass flow and the relative magnitude of the heat transfer, and its minimum value is the smallest of the two flows. This minimum determines the relative amount of heat transfer for a heat exchanger with maximum efficiency and cannot be exceeded. For more information, see the description of the block. Specific Dissipation Heat Transfer.

| Values |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

Thermal Liquid 1

#

Mass flow rate vector —

mass flow rate at each break point in the interpolation table for pressure drop

kg/s | kg/hr | kg/min | g/hr | g/min | g/s | t/hr | lbm/hr | lbm/min | lbm/s

Details

The mass flow rate at each break point in the interpolation table of differential pressure values. The unit interpolates and extrapolates the values of the break points to obtain a pressure drop value for any mass flow rate.

The mass flow values can be positive, zero, or negative and can cover laminar, transient, and turbulent zones. However, they should monotonously increase from left to right. Their number must match the size of the parameter. Pressure drop vector, with which they are combined to form tabular breakpoints.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Pressure drop vector —

pressure drop at each break point in the mass flow interpolation table

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

The pressure drop at each break point in the mass flow interpolation table. The unit interpolates and extrapolates the break points to obtain a pressure drop value for any mass flow rate.

The pressure drop values can be positive, zero, or negative and can cover laminar, transient, and turbulent zones. However, they should monotonously increase from left to right. Their number must match the size of the parameter. Mass flow rate vector, with which they are combined to form tabular breakpoints.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Reference inflow temperature —

the absolute temperature at the inlet, accepted in the tabular data

K | degC | degF | degR | deltaK | deltadegC | deltadegF | deltadegR

Details

The absolute inlet temperature is determined by collecting tabular pressure drop data. The reference temperature and inlet pressure determine the density of the liquid assumed in the tabular data. During the simulation, the ratio of the reference density of the liquid to the actual one is multiplied by the differential pressure value shown in the table to obtain the actual pressure drop.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Reference inflow pressure —

the absolute inlet pressure assumed in the tabular data

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

The absolute inlet pressure is determined by collecting tabular pressure drop data. The reference temperature and inlet pressure determine the density of the liquid assumed in the tabular data. During the simulation, the ratio of the reference density of the liquid to the actual one is multiplied by the differential pressure value shown in the table to obtain the actual pressure drop.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Mass flow rate threshold for flow reversal —

the upper bound of the numerically smoothed region for mass flow

kg/s | kg/hr | kg/min | g/hr | g/min | g/s | t/hr | lbm/hr | lbm/min | lbm/s

Details

The mass flow rate below which its value is numerically smoothed to avoid discontinuities that lead to simulation errors at zero flow. For more information about calculations, see the description of the block. Specific Dissipation Heat Exchanger Interface (TL).

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Thermal Liquid 1 volume —

the volume of liquid in the channel for supplying heat-conducting liquid 1

m^3 | um^3 | mm^3 | cm^3 | km^3 | ml | l | gal | igal | in^3 | ft^3 | yd^3 | mi^3

Details

The volume of liquid in the channel for supplying heat-conducting liquid 1.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Cross-sectional area at ports A1 and B1 —

the cross-sectional area of the flow at the inlet and outlet of the passage channel

m^2 | um^2 | mm^2 | cm^2 | km^2 | in^2 | ft^2 | yd^2 | mi^2 | ha | ac

Details

The cross-sectional area of the flow at the inlet and outlet of the channel for supplying heat-conducting liquid 1. The ports in the same channel have the same size.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Thermal liquid 2

#

Mass flow rate vector —

mass flow rate at each break point in the interpolation table for pressure drop

kg/s | kg/hr | kg/min | g/hr | g/min | g/s | t/hr | lbm/hr | lbm/min | lbm/s

Details

The mass flow rate at each break point in the interpolation table of differential pressure values. The unit interpolates and extrapolates the values of the break points to obtain a pressure drop value for any mass flow rate.

The mass flow values can be positive, zero, or negative and can cover laminar, transient, and turbulent zones. However, they should monotonously increase from left to right. Their number must match the size of the parameter. Pressure drop vector, with which they are combined to form tabular breakpoints.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Pressure drop vector —

pressure drop at each break point in the mass flow interpolation table

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

The pressure drop at each break point in the mass flow interpolation table. The unit interpolates and extrapolates the break points to obtain a pressure drop value for any mass flow rate.

The pressure drop values can be positive, zero, or negative and can cover laminar, transient, and turbulent zones. However, they should monotonously increase from left to right. Their number must match the size of the parameter. Mass flow rate vector, with which they are combined to form tabular breakpoints.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Reference inflow temperature —

the absolute temperature at the inlet, accepted in the tabular data

K | degC | degF | degR | deltaK | deltadegC | deltadegF | deltadegR

Details

The absolute inlet temperature is determined by collecting tabular pressure drop data. The reference temperature and inlet pressure determine the density of the liquid assumed in the tabular data. During the simulation, the ratio of the reference density of the liquid to the actual one is multiplied by the differential pressure value shown in the table to obtain the actual pressure drop.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Reference inflow pressure —

the absolute inlet pressure assumed in the tabular data

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

The absolute inlet pressure is determined by collecting tabular pressure drop data. The reference temperature and inlet pressure determine the density of the liquid assumed in the tabular data. During the simulation, the ratio of the reference density of the liquid to the actual one is multiplied by the differential pressure value shown in the table to obtain the actual pressure drop.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Mass flow rate threshold for flow reversal —

the upper bound of the numerically smoothed region for mass flow

kg/s | kg/hr | kg/min | g/hr | g/min | g/s | t/hr | lbm/hr | lbm/min | lbm/s

Details

The mass flow rate below which its value is numerically smoothed to avoid discontinuities that lead to simulation errors at zero flow. For more information about calculations, see the description of the block. Specific Dissipation Heat Exchanger Interface (TL).

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Thermal Liquid 2 volume —

the volume of liquid in the channel for supplying heat-conducting liquid 2

m^3 | um^3 | mm^3 | cm^3 | km^3 | ml | l | gal | igal | in^3 | ft^3 | yd^3 | mi^3

Details

The volume of liquid in the channel for supplying heat-conducting liquid 2.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Cross-sectional area at ports A2 and B2 —

the cross-sectional area of the flow at the inlet and outlet of the passage channel

m^2 | um^2 | mm^2 | cm^2 | km^2 | in^2 | ft^2 | yd^2 | mi^2 | ha | ac

Details

The cross-sectional area of the flow at the inlet and outlet of the channel for supplying heat-conducting liquid 2. The ports in the same channel have the same size.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Effects and Initial Conditions

# Thermal Liquid 1 dynamic compressibility — the possibility of modeling the pressure dynamics in the channel for the supply of heat-conducting liquid 1

Details

The ability to simulate pressure dynamics in a channel for supplying a heat-conducting liquid 1. If you uncheck this box, the unit will remove pressure derivatives from the equations of conservation of energy and mass of components. The pressure inside the heat exchanger will be reduced to a weighted average of the two inlet pressures.

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

#

Thermal Liquid 1 initial temperature —

temperature in the heat-conducting liquid 1 at the beginning of the simulation

K | degC | degF | degR | deltaK | deltadegC | deltadegF | deltadegR

Details

The temperature in the channel for the supply of heat-conducting liquid 1 at the beginning of the simulation.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Thermal Liquid 1 initial pressure —

pressure in the channel for supplying heat-conducting liquid 1 at the beginning of the simulation

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

Pressure in the channel for supplying heat-conducting liquid 1 at the beginning of the simulation.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

# Thermal Liquid 2 dynamic compressibility — the possibility of modeling the pressure dynamics in the channel for the supply of heat-conducting liquid 2

Details

The possibility of modeling the pressure dynamics in the channel for the supply of heat-conducting liquid 2. If you uncheck this box, the block will remove the pressure derivatives from the equations of conservation of energy and mass of the components. The pressure inside the heat exchanger will be reduced to a weighted average of the two inlet pressures.

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

#

Thermal Liquid 2 initial temperature —

the temperature in the heat-conducting liquid 2 at the beginning of the simulation

K | degC | degF | degR | deltaK | deltadegC | deltadegF | deltadegR

Details

The temperature in the heat-conducting fluid supply channel 2 at the beginning of the simulation.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Thermal Liquid 2 initial pressure —

pressure in the channel for the supply of heat-conducting liquid 2 at the beginning of the simulation

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

The pressure in the channel for the supply of heat-conducting liquid 2 at the beginning of the simulation.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |