Single-Acting Actuator (TL)

A one-way linear actuator in a heat-conducting fluid network.

blockType: EngeeFluids.ThermalLiquid.Actuators.TranslationalSingleActing

Path in the library: |

Description

Block Single-Acting Actuator (TL) It simulates a linear actuator, the piston of which is controlled by a chamber with a thermally conductive liquid. The drive creates a reciprocating motion of the piston, the force of which is determined by the overpressure of the chamber with a heat-conducting liquid.

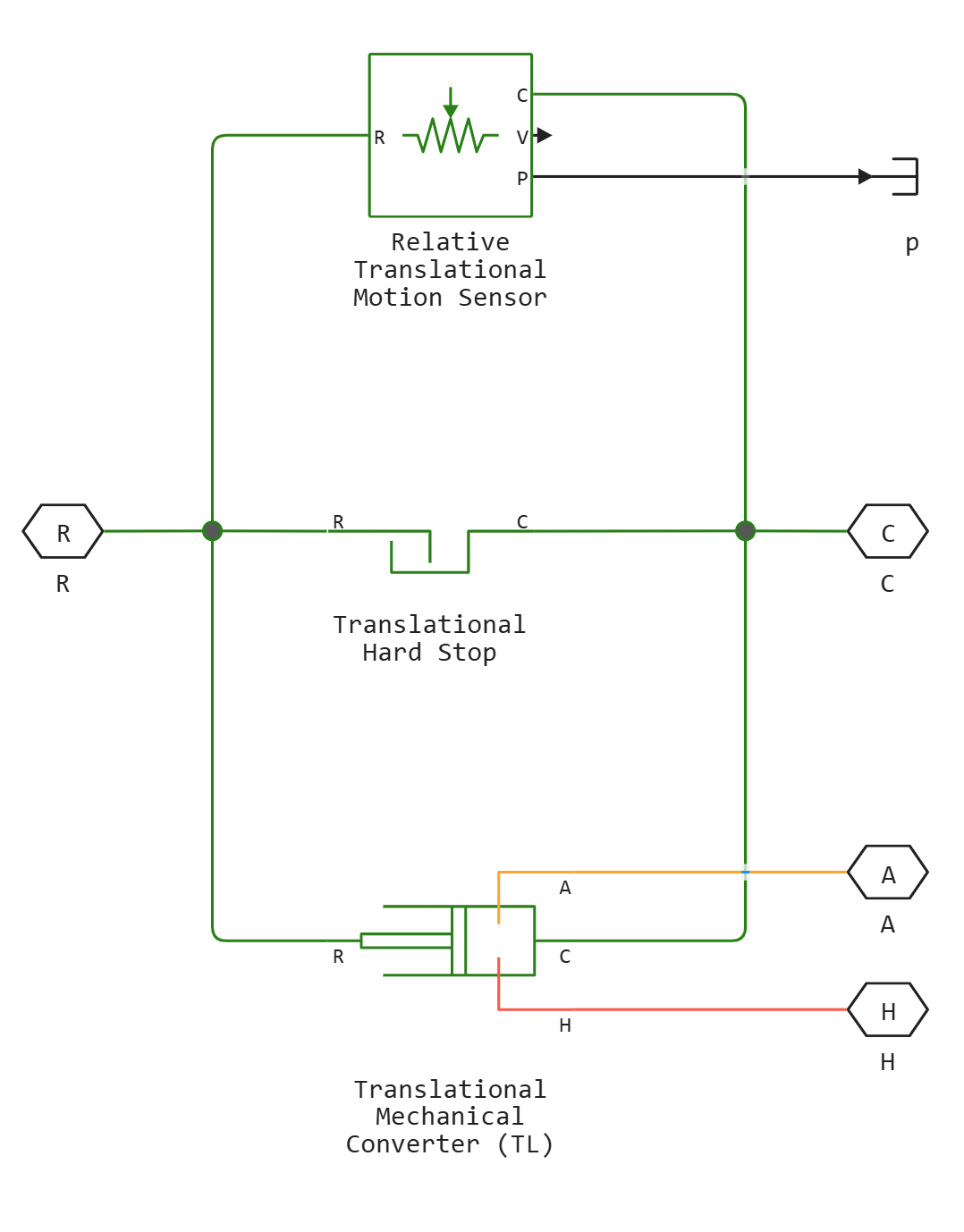

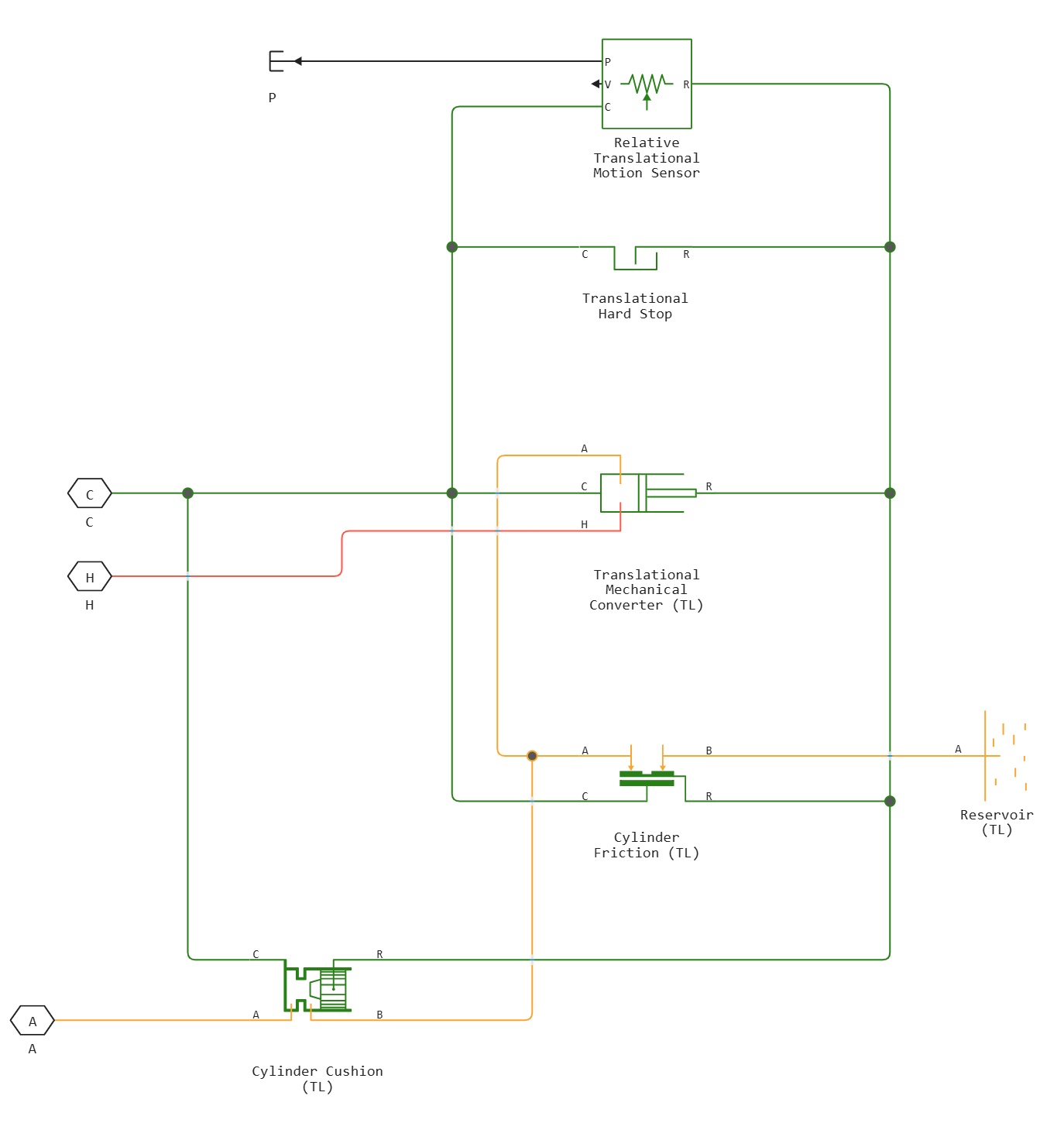

The figure shows the main drive components for different parameter values. Mechanical orientation. Port A is the entrance to the chamber of a thermally conductive liquid. Port R is associated with the piston, and port C is associated with the drive housing. The H port provides thermal interaction between the heat-conducting liquid and the environment.

Moving

The movement of the piston is determined by the displacement of port R relative to port C. The direction of movement of the piston is set by the parameter Mechanical orientation. The movement of the piston is neutral (equal to 0), when the volume of the camera is Dead volume.

The direction of movement of the piston depends on the parameter Mechanical orientation. If the mechanical orientation is positive, then the movement of the piston will be positive with respect to the actuator body when the gauge pressure in port A is positive. The direction of movement is reversed if the mechanical orientation is negative.

The rigid stop model

The movement of the piston is limited by a pair of rigid stops located within the stroke of the piston. The block uses the same model of rigid stops as the block Translational Hard Stop, and takes into account the damping and stiffness coefficients at both ends of the piston stroke.

If the movement of the piston is positive, then the lower rigid stop is on , and the upper hard focus is on . If the movement of the piston is negative, then the lower rigid stop is at the point , and the top one is at the point .

The damper

This unit can simulate a damper at the extreme points of the piston stroke. Select an option Cylinder end cushioning to slow down the movement of the piston as it approaches the maximum elongation determined by the parameter Piston stroke.

Friction

This unit can simulate friction against the movement of a piston. If you set the parameter Cylinder friction The resulting friction is a combination of the effects of Strobeck, Coulomb, and viscosity. The unit measures the pressure difference between the pressure in the chamber and the ambient pressure.

Block sub-components

Block Single-Acting Actuator (TL) It consists of blocks:

The structural diagram of the drive is shown in the diagram.

If you check the option boxes Cylinder friction or Cylinder end cushioning The block composition will also include the following blocks Cylinder Friction (TL) or Cylinder Cushion (TL).

Ports

Conserving

#

H

—

heat port

heat

Details

A port relating to the thermal conductivity of a thermal liquid.

| Program usage name |

|

#

C

—

drive housing

translational mechanics

Details

Mechanical progressive port corresponding to the actuator housing.

| Program usage name |

|

#

A

—

inlet or outlet for thermal liquid

thermal liquid

Details

The port corresponding to the thermal liquid entering or leaving the chamber.

| Program usage name |

|

#

R

—

actuator piston

translational mechanics

Details

A mechanical progressive port corresponding to the actuator piston.

| Program usage name |

|

Output

#

p

—

piston position

scalar

Details

Piston position in m.

| Data types |

|

| Complex numbers support |

No |

Parameters

Actuator

#

Mechanical orientation —

the direction of movement of the piston

Pressure at A causes positive displacement of R relative to C | Pressure at A causes negative displacement of R relative to C

Details

Determines the direction of displacement of the piston. Options to choose from:

-

Pressure at A causes positive displacement of R relative to C— the movement of the piston is positive if the volume of liquid in port A increases. This corresponds to the movement of the rod out of the cylinder. -

Pressure at A causes negative displacement of R relative to C— the movement of the piston is negative if the volume of liquid in port A increases. This corresponds to the movement of the rod inside the cylinder.

| Values |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

#

Piston cross-sectional area —

the cross-sectional area of the piston rod

m^2 | um^2 | mm^2 | cm^2 | km^2 | in^2 | ft^2 | yd^2 | mi^2 | ha | ac

Details

The cross-sectional area of the piston rod.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Piston stroke —

stroke of the piston

m | um | mm | cm | km | in | ft | yd | mi | nmi

Details

The maximum possible displacement of the piston.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Dead volume —

the volume of liquid in the chamber at which the piston movement is 0

m^3 | um^3 | mm^3 | cm^3 | km^3 | ml | l | gal | igal | in^3 | ft^3 | yd^3 | mi^3

Details

The volume of liquid at the value of the piston displacement 0. This volume of liquid corresponds to the position of the piston, at which it is located at the top in relation to the end cap of the actuator.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Environment pressure specification —

the method of setting the ambient pressure

Atmospheric pressure | Specified pressure

Details

The method of setting the ambient pressure. Option Atmospheric pressure sets the ambient pressure equal to 0.101325 MPa.

| Values |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

#

Environment pressure —

ambient pressure

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

User-defined ambient pressure.

Dependencies

To use this parameter, set for the parameter Environment pressure specification meaning Specified pressure.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Hard Stop

#

Hard stop model —

choosing a rigid stop model

Stiffness and damping applied smoothly through transition region, damped rebound | Full stiffness and damping applied at bounds, undamped rebound | Full stiffness and damping applied at bounds, damped rebound | Based on coefficient of restitution

Details

Selecting a model for the force acting on the piston when it is in extreme positions. For more information, see the block Translational Hard Stop.

| Values |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

#

Hard-stop stiffness coefficient —

stiffness coefficient

N/m | mN/m | kN/m | MN/m | GN/m | kgf/m | lbf/ft | lbf/in

Details

The coefficient of piston stiffness.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Hard-stop damping coefficient —

damping coefficient

N*s/m | kgf*s/m | lbf*s/ft | lbf*s/in

Details

Piston damping coefficient.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Transition region —

range of action of the rigid stop model

m | um | mm | cm | km | in | ft | yd | mi | nmi

Details

The area of operation of the rigid stop. Outside of this range for the extreme positions of the piston Hard stop model it is not applied, and the additional force from the stop side does not act on the piston.

Dependencies

To use this parameter, set for the parameter Hard stop model meaning Stiffness and damping applied smoothly through transition region, damped rebound.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

# Coefficient of restitution — the ratio of the final and initial relative velocity between the rod and the stop after a collision

Details

The ratio of the final and initial relative velocity between the rod and the stop after the rod rebounds.

Dependencies

To use this parameter, set for the parameter Hard stop model meaning Based on coefficient of restitution.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Static contact speed threshold —

threshold value of the relative velocity between the rod and the stop before the collision

m/s | mm/s | cm/s | km/s | m/hr | km/hr | in/s | ft/s | mi/s | ft/min | mi/hr | kn

Details

The threshold value of the relative velocity between the rod and the stop before the collision. If the rod hits the housing at a speed lower than the value of this parameter, they remain in contact. Otherwise, the rod bounces off. To avoid simulating static contact between the rod and the housing, set this parameter to 0.

Dependencies

To use this parameter, set for the parameter Hard stop model meaning Based on coefficient of restitution.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Static contact release force threshold —

the threshold value of the force required to transition from the contact state to the free state

N | nN | uN | mN | kN | MN | GN | dyn | lbf | kgf

Details

The minimum force required to remove the rod from the static contact state.

Dependencies

To use this parameter, set for the parameter Hard stop model meaning Based on coefficient of restitution.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Cushion

# Cylinder end cushioning — the option of modeling piston braking due to the action of a damper

Details

Select this option to enable piston deceleration in its extreme positions. For more information, see the section Cylinder Cushion (TL).

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

#

Cushion plunger cross-sectional area —

the cross-sectional area of the shock-absorbing plunger

m^2 | um^2 | mm^2 | cm^2 | km^2 | in^2 | ft^2 | yd^2 | mi^2 | ha | ac

Details

The cross-sectional area of the shock-absorbing plunger.

Dependencies

To use this option, select the option checkbox. Cylinder end cushioning.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Cushion plunger length —

the length of the shock-absorbing plunger

m | um | mm | cm | km | in | ft | yd | mi | nmi

Details

The length of the shock-absorbing plunger.

Dependencies

To use this option, select the option checkbox. Cylinder end cushioning.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Cushion orifice area —

the area of the opening between the damper chambers

m^2 | um^2 | mm^2 | cm^2 | km^2 | in^2 | ft^2 | yd^2 | mi^2 | ha | ac

Details

The area of the opening between the damper chambers.

Dependencies

To use this option, select the option checkbox. Cylinder end cushioning.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Leakage area between plunger and cushion sleeve —

the area of the gap between the damper plunger and the bushing

m^2 | um^2 | mm^2 | cm^2 | km^2 | in^2 | ft^2 | yd^2 | mi^2 | ha | ac

Details

The area of the gap between the damper plunger and the bushing. The parameter supports computational stability of the simulation, ensuring continuity of the flow.

Dependencies

To use this option, select the option checkbox. Cylinder end cushioning.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Check valve cracking pressure differential —

the pressure drop at which the check valve begins to open

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

The pressure at which the valve is triggered. When the pressure difference in port A and corresponds to or exceeds the value of this parameter, the non-return valve of the damper begins to open.

Dependencies

To use this option, check the option box. Cylinder end cushioning.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Check valve maximum pressure differential —

the pressure drop required to fully open the check valve

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

Maximum pressure drop of the damper check valve. This parameter sets the upper pressure limit so that the system pressure remains realistic.

Dependencies

To use this option, check the option box. Cylinder end cushioning.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Check valve maximum area —

the area of the fully open check valve

m^2 | um^2 | mm^2 | cm^2 | km^2 | in^2 | ft^2 | yd^2 | mi^2 | ha | ac

Details

The cross-sectional area of the non-return valve opening in the fully open position.

Dependencies

To use this option, check the option box. Cylinder end cushioning.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Check valve leakage area —

leakage area with the check valve fully closed

m^2 | um^2 | mm^2 | cm^2 | km^2 | in^2 | ft^2 | yd^2 | mi^2 | ha | ac

Details

The total area of possible leaks when the check valve is fully closed. Any area less than this value increases smoothly to the specified leakage area. This value contributes to computational robustness by maintaining continuity of flow.

Dependencies

To use this option, select the option checkbox. Cylinder end cushioning.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

# Smoothing factor — numerical smoothing factor

Details

The continuous smoothing coefficient, which ensures smooth opening by correcting the valve characteristics in the almost open and almost closed positions. Set a non-zero value less than one to increase the stability of the simulation in these modes.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Friction

# Cylinder friction — option to simulate friction during piston movement

Details

Whether the friction of the piston is taken into account during movement. The friction force of the block consists of the Shtribek force, Coulomb force and viscosity.

Select this option to enable piston friction during movement. The friction force of the block consists of the Shtribek force, Coulomb force and viscosity. For more information, see the section Cylinder Cushion (TL).

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

# Breakaway to Coulomb friction force ratio — the ratio of the separation force to the Coulomb friction force

Details

The ratio of the separation force to the Coulomb friction force.

Dependencies

To use this option, select the option checkbox. Cylinder friction.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Breakaway friction velocity —

threshold of movement against the friction force

m/s | mm/s | cm/s | km/s | m/hr | km/hr | in/s | ft/s | mi/s | ft/min | mi/hr | kn

Details

The threshold value for movement against the friction force.

Dependencies

To use this option, select the option checkbox. Cylinder friction.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Preload force —

the initial force in the cylinder, which occurs during the assembly of the seal, N

N | nN | uN | mN | kN | MN | GN | dyn | lbf | kgf

Details

The initial force in the cylinder under the action of the seal assembly. The block uses this parameter to calculate the Coulomb friction force.

Dependencies

To use this option, select the option checkbox. Cylinder friction.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Coulomb friction force coefficient —

coefficient of Coulomb friction force

m^2 | um^2 | mm^2 | cm^2 | km^2 | in^2 | ft^2 | yd^2 | mi^2 | ha | ac | N/Pa

Details

The coefficient of Coulomb friction force. The block uses this parameter to calculate the Coulomb friction force.

Dependencies

To use this option, select the option checkbox. Cylinder friction.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Viscous friction coefficient —

coefficient of viscous friction

N*s/m | kgf*s/m | lbf*s/ft | lbf*s/in

Details

Coefficient of viscous friction. This parameter is used to calculate the viscous friction force.

Dependencies

To use this option, select the option checkbox. Cylinder friction.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Initial Conditions

#

Initial piston displacement —

the initial position of the piston

m | um | mm | cm | km | in | ft | yd | mi | nmi

Details

The position of the piston at the beginning of the simulation.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

# Fluid dynamic compressibility — the option of modeling the compressibility of a liquid

Details

Check this box to enable changes in the density of the liquid due to its compressibility. If the check box is selected Fluid dynamic compressibility, then the changes associated with the mass flow rate of the fluid in the block are calculated in addition to the density changes associated with pressure changes. In the library Isothermal liquid all blocks calculate density as a function of pressure.

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

#

Initial liquid pressure —

initial fluid pressure for compressible fluids

Pa | uPa | hPa | kPa | MPa | GPa | kgf/m^2 | kgf/cm^2 | kgf/mm^2 | mbar | bar | kbar | atm | ksi | psi | mmHg | inHg

Details

The initial fluid pressure for compressible fluids.

Dependencies

To use this option, check the box Fluid dynamic compressibility.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Initial liquid temperature —

initial fluid pressure for compressible fluids

K | degC | degF | degR | deltaK | deltadegC | deltadegF | deltadegR

Details

The initial fluid pressure for compressible fluids.

Dependencies

To use this option, check the box Fluid dynamic compressibility.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |