Planetary Gear

Gear transmission with solar, planetary and ring gears.

blockType: Engee1DMechanical.Transmission.Gears.Planetary.SingleStage

Path in the library: |

Description

Block Planetary Gear simulates a gear train with solar, planetary, and annular gears. Planetary gears are often found in transmission systems, where they provide high gear ratios with compact overall dimensions. The carrier connected to the drive shaft holds the planetary gears. Ports C, R and S are shafts connected to the planetary gear drive, ring and solar gears.

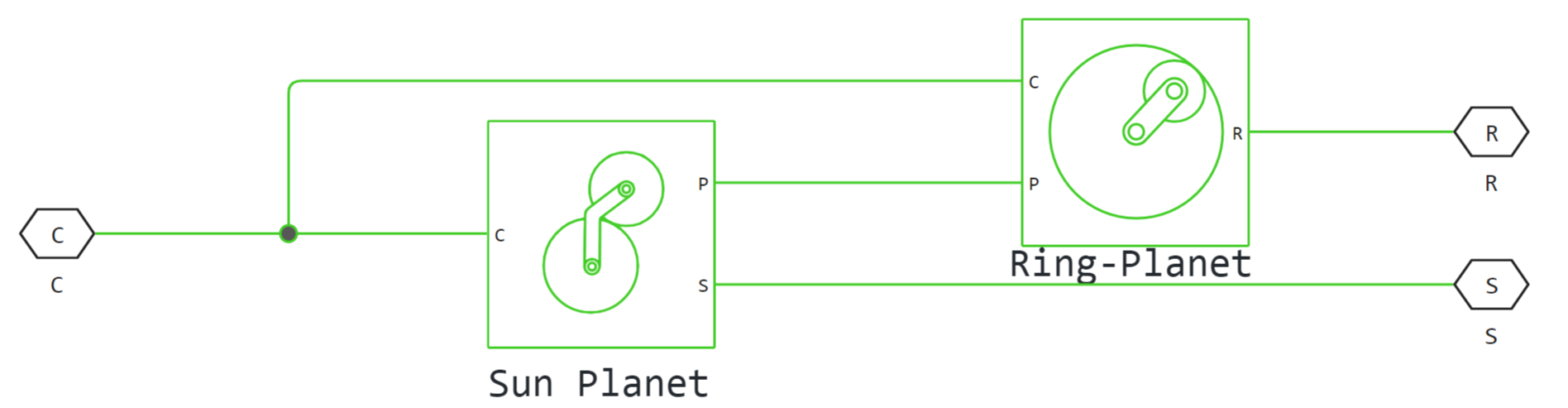

This block models planetary transmission as a block-based structural component. Sun-Planet and Ring-Planet. The figure shows a block diagram of this structural component.

To improve the accuracy of the gear model, you can set properties such as gear inertia, engagement losses, and viscous friction losses. By default, inertia and viscous losses of the gear are assumed to be negligible. This unit allows you to set the inertia of the internal planetary gears. To simulate the inertia of the driving, solar and ring gears, connect the blocks Inertia to ports C, S, and R.

The thermal model

You can simulate the effects of heat flow and temperature changes by turning on an additional heat port. To use the thermal port, set the Friction model parameter to `Temperature-dependent efficiency'.

The equations

Ideal gears and transmission ratios

Block Planetary Gear It imposes two kinematic and two geometric constraints.:

where

-

— radius of the driving gear;

-

— radius of the solar gear;

-

— angular velocity of the solar gear;

-

— the radius of the planetary transmission;

-

— angular velocity of the planetary gear;

-

— the radius of the ring gear.

The gear ratio of the ring and sun gears is equal to:

where — the number of teeth on each gear.

From the point of view of this relation, the key kinematic constraint is:

The four degrees of freedom are reduced to two independent pairs of gears: ( , ) or ( , ).

Gear ratio it must be >1.

|

The transmission of torque is carried out as follows:

where

-

— the torque transmission coefficient for the solar gear;

-

— torque transmission coefficient for ring transmission;

-

— losses during transmission of torque.

Ideally, when there is no loss in torque transmission, .

Imperfect limitations and losses in gears

In an imperfect case . For more information, see the article Modeling of mechanical gears with losses.

Assumptions and limitations

-

The inertia of the gears is negligible.

-

Gears are treated as solids.

-

Coulomb friction slows down the simulation. (for more information, see here)

Ports

Conserving

#

C

—

planetary gear drive

`rotational mechanics

Details

A non-directional port associated with the driver of a planetary gear.

| Program usage name |

|

#

R

—

ring gear

`rotational mechanics

Details

A non-directional port associated with a ring gear.

| Program usage name |

|

#

S

—

sun gear

`rotational mechanics

Details

A non-directional port associated with the sun gear.

| Program usage name |

|

#

H

—

heat flux

`heat

Details

A non-directional port associated with heat flow.

The heat port allows modelling the heat flow between the unit and the connected network.

Dependencies

To use this port, set Friction model to `Temperature-dependent efficiency'.

| Program usage name |

|

Parameters

Main

# Ring (R) to sun (S) teeth ratio (NR/NS) — gear ratio from ring gear to sun gear

Details

A constant gear ratio, , of ring gear revolutions to sun gear revolutions, determined by the number of ring gear teeth divided by the number of sun gear teeth. The gear ratio must be strictly > 1.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Meshing Losses

#

Friction model —

friction model

No meshing losses - Suitable for HIL simulation | Constant efficiency | Temperature-dependent efficiency

Details

A model of friction in transmission:

-

No meshing losses - Suitable for HIL simulation- the gearing is assumed to be perfect; -

Constant efficiency- torque transmission between gear pairs is reduced by a constant efficiency value , such that . -

`Temperature-dependent efficiency' - the torque transmission between gear pairs is determined by an interpolation table of temperature and efficiency.

| Values |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

# Sun-planet and ring-planet ordinary efficiency — Efficiency of torque transmission from sun gear to planetary gear and from ring gear to planetary gear

Details

The vector of efficiency values, [ ], for the following gears: sun gear-planetary gear and ring gear-planetary gear, respectively.

Dependencies

To use this parameter, set the Friction model parameter to `Constant efficiency'.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Temperature —

vector of temperature values

K | degC | degF | degR | deltaK | deltadegC | deltadegF | deltadegR

Details

A vector of temperature values used to construct an interpolation table of temperature and efficiency correspondence. The elements of the vector should be monotonically increasing.

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

# Sun-planet efficiency — vector of torque transmission efficiency values from solar to planetary gears

Details

Vector of torque transmission efficiency values, [ ], for the gear mesh of the sun gear and planetary gear.

Each element is an efficiency value related to the corresponding temperature value in the Temperature parameter value vector. The length of the vector must be equal to the length of the Temperature parameter vector. Each element of the vector must be in the range (0,1].

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

# Ring-planet efficiency — vector of torque transmission efficiency values from ring gear to planetary gear

Details

Vector of torque transmission efficiency values, [ ], of ring gear to planetary gear.

Each element is an efficiency value related to the corresponding temperature value in the Temperature parameter value vector. The length of the vector must be equal to the length of the Temperature parameter vector. Each element of the vector must be in the range (0,1].

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Sun-carrier and planet-carrier power thresholds —

minimum threshold power values

W | uW | mW | kW | MW | GW | V*A | HP_DIN

Details

Vector of power threshold values above which full torque transmission efficiency values apply. Enter the threshold values in the order solar-planetary gear, ring-planetary gear, ring-planetary gear. For values below these values, the efficiency is smoothed using a hyperbolic tangent function.

-

If Friction model is set to `Constant efficiency', the unit reduces losses to zero when no power is transmitted.

-

If Friction model is set to `Temperature-dependent efficiency', the unit smooths the efficiency values between zero at rest and the values specified in the temperature and efficiency interpolation tables.

Dependencies

To use this parameter, set Friction model to Constant efficiency or Temperature-dependent efficiency.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Viscous Losses

#

Sun-carrier and planet-carrier viscous friction coefficients —

viscous friction coefficients between gears

N*m*s/rad | mN*m*s/rad | kN*m*s/rad | kgf*m*s/rad | lbf*ft*s/rad

Details

The vector of viscous friction coefficients, [ ], for the motion of the sun gear and planetary gear, respectively.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Inertia

# Inertia — inertia model

Details

Select this check box to enable the inertia model for this block.

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

#

Planet gear inertia —

planetary gear inertia

kg*m^2 | g*m^2 | kg*cm^2 | g*cm^2 | lbm*in^2 | lbm*ft^2 | slug*in^2 | slug*ft^2

Details

Inertia of a planetary gear as a positive scalar.

Dependencies

To use this parameter, select the checkbox for the Inertia parameter.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Thermal Port

#

Thermal mass —

heat capacity

J/K | kJ/K

Details

The heat energy required to change the temperature of a component by one degree. The greater the heat capacity, the more resistant the component is to temperature change.

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Initial temperature —

initial temperature

K | degC | degF | degR | deltaK | deltadegC | deltadegF | deltadegR

Details

The temperature of the block at the beginning of the simulation. The initial temperature sets the initial efficiency value of the components according to the vectors specified for them.

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Additional Info

Simulation of hardware in a circuit

For optimal simulation performance, set the Friction model to the default value, `No meshing losses - Suitable for HIL simulation'.