Differential

A gear mechanism that allows the driven shafts to rotate at different speeds.

blockType: Engee1DMechanical.Transmission.Gears.Differentials.Open

Path in the library: |

Description

A Differential unit is a gear mechanism that allows driven gears to rotate at different speeds. Differentials are often found in automobiles where they allow different wheels to rotate at different speeds when cornering. The D, S1, and S2 ports represent the longitudinal drive shaft and sun gear shafts of the differential respectively. Either of these shafts can drive the other two.

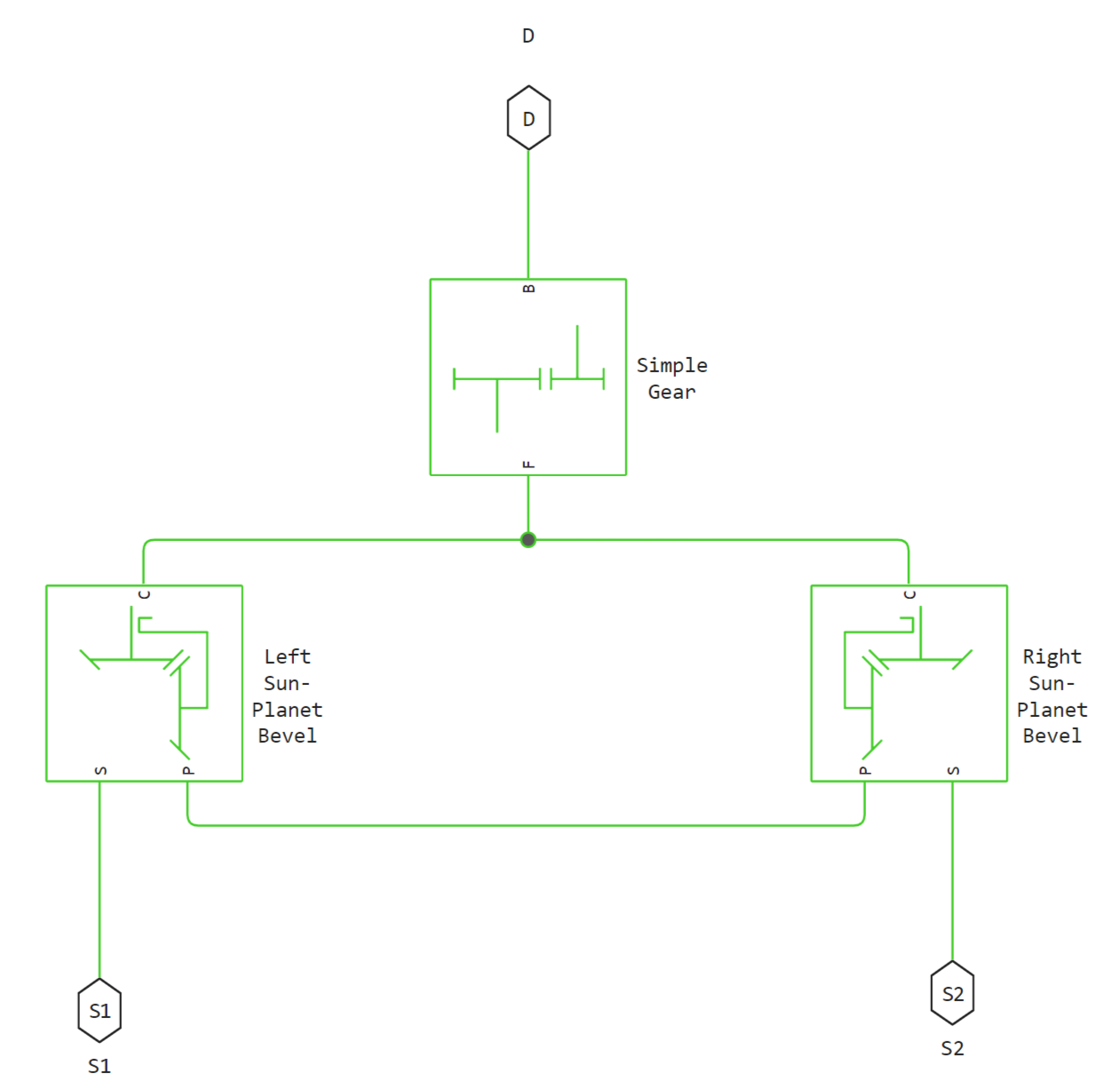

This block models the differential mechanism as a structural component based on the blocks Simple Gear and Sun-Planet Bevel.

The figure shows the equivalent block diagram for the Differential block.

To increase the accuracy of the gear model, you can set properties such as gear inertia and viscous friction losses in the gear. By default, inertia and viscous losses are assumed to be negligible.

This block allows you to specify the inertia of the drive pinion and internal planetary gears. To simulate the inertia of the driven gears, connect the Inertia block to ports D, S1 and S2.

Thermal model

You can model the effects of heat flow and temperature changes by enabling the optional H heat port. To use the H thermal port, set the Friction model parameter to `Temperature-dependent efficiency'.

Equations

Ideal gears and gear ratios

The Differential block imposes one kinematic constraint on three linked axes:

where

-

- is the rotation speed of the sun gear shaft S1;

-

- is the rotation speed of the sun gear shaft S2.

Negative values mean that the differential is to the left of the centreline. The three degrees of freedom are reduced to two independent pairs of gears: ( ) and ( ). - is the drive pinion.

The sum of the lateral motions is the transformed longitudinal motion. The difference of the lateral movements, , is independent of the longitudinal movement. The total motion of the side gears is a superposition of these two independent degrees of freedom, which have the following physical meaning:

-

The longitudinal degree of freedom is equivalent to the two side shafts rotating at the same angular velocity, , and at a fixed ratio with respect to the longitudinal shaft.

-

A differential degree of freedom is equivalent to the longitudinal drive shaft remaining locked, , where is the speed of the drive shaft and the side shafts rotate relative to each other in opposite directions, .

The torques of the lateral axes are limited by the torque of the longitudinal axis such that the total power flow is zero:

where

-

and are the torques along the lateral axes;

-

- longitudinal torque;

-

- power loss.

In the ideal case, when kinematic and power constraints are combined, we obtain the following relation:

where is the ratio for the longitudinal drive shaft.

Ideal limits

The effective constraint of a Differential block consists of two subconstraints of a bevel planetary gearbox.

-

The first sub-limit is related to the connection of the two bevel gears to the drive part:

where and are the gear ratios for the solar-planetary gear pairs.

-

The second sub-limit is related to the connection of the drive pinion in planetary mechanisms with the drive shaft:

The gear ratios of bevel planetary gears, depending on the radii of the sunwheels and planetary wheels, are represented in the following form:

The Differential block is implemented taking into account that , leaving free for customisation.

Non-ideal gears and losses in gears

In the non-ideal case (see Modeling of mechanical gears with losses) for details.

Assumptions and limitations

-

The inertia of the gears is negligible.

-

The gears are treated as solids.

-

Coulomb friction slows down the simulation (see here for details).

Ports

Conserving

#

D

—

drive shaft

`rotational mechanics

Details

A non-directional port associated with a longitudinal drive shaft.

| Program usage name |

|

#

S1

—

sun gear S1

`rotational mechanics

Details

Non-directional port associated with the sun gear S1.

| Program usage name |

|

#

S2

—

sun gear S2

`rotational mechanics

Details

Non-directional port associated with the sun gear S2.

| Program usage name |

|

#

H

—

heat flux

`heat

Details

A non-directional port associated with heat flow.

The heat port allows modelling the heat flow between the unit and the connected network.

Dependencies

To use this port, set Friction model to `Temperature-dependent efficiency'.

| Program usage name |

|

Parameters

Main

#

Crown gear located —

ring gear arrangement

To the left of centerline | To the right of centerline

Details

The position of the bevel ring gear in relation to the centre line of the gearbox.

| Values |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

# Carrier (C) to driveshaft (D) teeth ratio (NC/ND) — drive pinion to drive shaft pinion ratio

Details

A constant ratio, , of the drive pinion revolutions to the longitudinal rotation of the drive shaft pinion, determined by the number of teeth of the drive pinion divided by the number of teeth of the drive shaft pinion. This ratio must be `>0'.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Meshing Losses

#

Friction model —

friction model

No meshing losses - Suitable for HIL simulation | Constant efficiency | Temperature-dependent efficiency

Details

A model of friction in a transmission. Defined as:

-

No meshing losses - Suitable for HIL simulation- the gearing is assumed to be perfect. -

Constant efficiency- torque transmission between gear pairs is reduced by a constant efficiency value, , so that . -

Temperature-dependent efficiency- the torque transmission between gear pairs is determined by an interpolation table of temperature and efficiency correspondence.

| Values |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

# Sun-sun and carrier-driveshaft ordinary efficiencies — vector of torque transmission efficiency values

Details

Vector of efficiency values, [ ], from master to driven sun gear and from carrier to longitudinal drive shaft, respectively. The elements of the vector must be in the range (0,1].

Dependencies

To use this parameter, set the Friction model parameter to Constant efficiency.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Temperature —

vector of temperature values

K | degC | degF | degR | deltaK | deltadegC | deltadegF | deltadegR

Details

A vector of temperature values used to construct an interpolation table of temperature and efficiency correspondence. The elements of the vector should be monotonically increasing.

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

# Sun-sun efficiency — vector of torque transmission efficiency values from the driving sun gear to the driven sun gear

Details

A vector of output to input power ratio values describing the power flow from the master solar to the driven solar gear, . The unit uses these values to build an interpolation table of temperature and efficiency correspondence.

Each element is an efficiency value related to the corresponding temperature value in the vector of Temperature parameter values. The length of the vector must be equal to the length of the Temperature parameter vector. Each element of the vector must be in the range (0,1].

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

# Carrier-driveshaft efficiency — vector of torque transmission efficiency values from the drive pinion to the drive shaft

Details

A vector of output to input power ratios describing the power flow from the drive pinion to the drive shaft, . The unit uses these values to build an interpolation table of temperature and efficiency correspondence.

Each element is an efficiency value related to the corresponding temperature value in the vector of Temperature parameter values. The length of the vector must be equal to the length of the Temperature parameter vector. Each element of the vector must be in the range (0,1].

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Sun-carrier and driveshaft-casing power thresholds —

minimum threshold power values

W | uW | mW | kW | MW | GW | V*A | HP_DIN

Details

Power threshold vector for the sun gear and drive shaft [ ] respectively. Above these values, the values of full efficiencies are applied. Below these values, the hyperbolic tangent function smooths the efficiency values.

-

By setting the Friction model parameter to `Constant efficiency', the unit reduces losses to zero when no power is transmitted.

-

If the Friction model is set to `Temperature-dependent efficiency', the unit smooths the efficiency values between zero at rest and the values given in the temperature and efficiency interpolation tables.

Dependencies

To use this parameter, set Friction model to `Constant efficiency' or `Temperature-dependent efficiency'.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Viscous Losses

#

Sun-carrier and driveshaft-casing viscous friction coefficients —

viscous friction coefficients between gears

N*m/(rad/s) | ft*lbf/(rad/s)

Details

Vector of viscous friction coefficients, [ ], for planetary gear and drive shaft respectively.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Inertia

# Inertia — inertia model

Details

Select this check box to enable the inertia model for the gear.

| Default value |

|

| Program usage name |

|

| Evaluatable |

No |

#

Carrier inertia —

moment of inertia of the drive pinion

kg*m^2 | g*m^2 | kg*cm^2 | g*cm^2 | lbm*in^2 | lbm*ft^2 | slug*in^2 | slug*ft^2

Details

Moment of inertia of the planetary drive gear.

Dependencies

To use this parameter, select the check box for Inertia.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Planet gear inertia —

moment of inertia of the planetary gear

kg*m^2 | g*m^2 | kg*cm^2 | g*cm^2 | lbm*in^2 | lbm*ft^2 | slug*in^2 | slug*ft^2

Details

Moment of inertia of the planetary gear.

Dependencies

To use this parameter, select the check box for the Inertia parameter.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

Thermal Port

#

Thermal mass —

heat capacity

J/K | kJ/K

Details

The heat energy required to change the temperature of a component by one degree. The greater the heat capacity, the more resistant the component is to temperature change.

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |

#

Initial temperature —

initial temperature

K | degC | degF | degR | deltaK | deltadegC | deltadegF | deltadegR

Details

The temperature of the block at the beginning of the simulation. The initial temperature sets the initial efficiency value of the components according to the vectors specified for them.

Dependencies

To use this parameter, set the Friction model parameter to `Temperature-dependent efficiency'.

| Units |

|

| Default value |

|

| Program usage name |

|

| Evaluatable |

Yes |