Simulation of an automatic liquid level control system in a tank

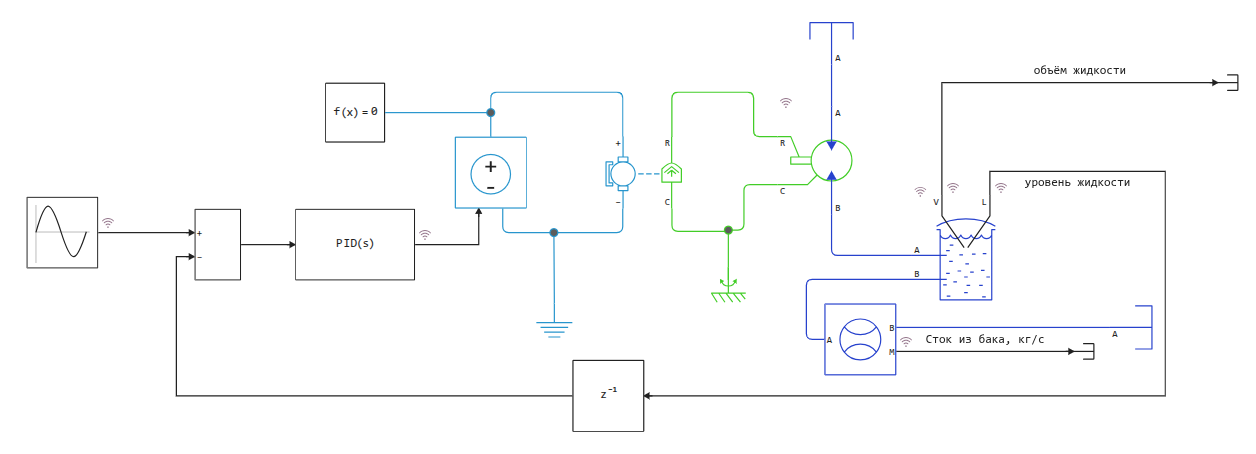

This example demonstrates a model of a tank liquid level control system based on physical components.

The model is a closed control loop, where liquid enters the tank through a controlled pump, and flows out through an outlet characterized by hydraulic resistance. The level sensor continuously measures the current height of the liquid column in the tank and transmits this signal to the control unit.

Model diagram:

Running the simulation

engee.open("$(@__DIR__)/liquid_level_control_system.engee");

engee.run("liquid_level_control_system");

Isolation of liquid level and setpoint signals from the simout variable:

result = simout;

res = collect(result);

Writing signals to variables:

level = collect(res[15])

sin_sig = collect(res[24])

tank_mfr = collect(res[11])

pump_mfr = collect(res[25]);

Visualization of simulation results

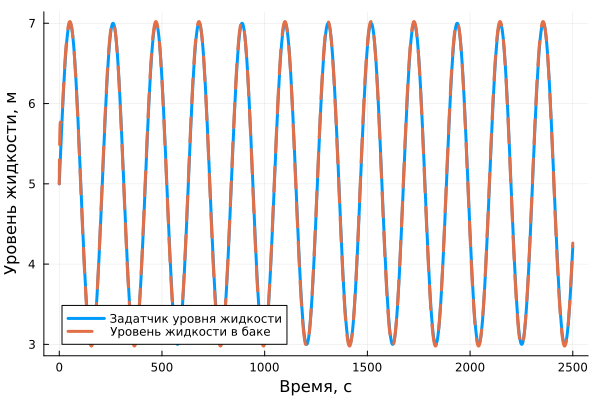

Liquid level graph and setpoint signal:

using Plots

gr()

plot(sin_sig[:,1], sin_sig[:,2], label="Liquid level sensor", linewidth=3, xlabel="Time, from", ylabel="Liquid level, m")

plot!(level[:,1], level[:,2], label="Liquid level in the tank", linewidth=3, linestyle=:dash)

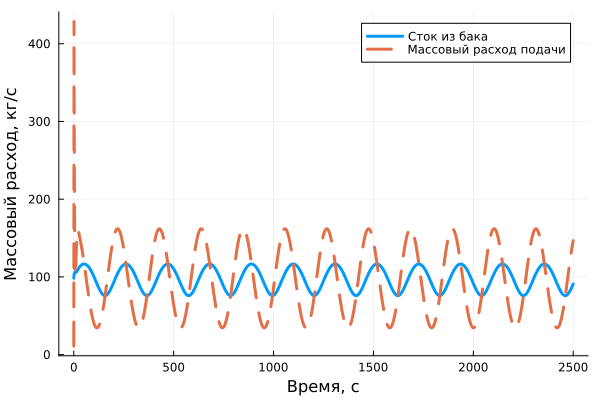

Graph of the mass flow rate of the liquid passing through the pump and through the outlet of the tank:

plot(tank_mfr[:,1], tank_mfr[:,2], label="Drain from the tank", linewidth=3, xlabel="Time, from", ylabel="Mass flow rate, kg/s")

plot!(pump_mfr[:,1], pump_mfr[:,2], label="Mass flow rate of the feed", linewidth=3, linestyle=:dash)

Conclusions:

In this example, a simulation of an automatic liquid level control system in a tank was demonstrated. Such models can be used to optimize a wide range of processes, starting with filling a water tower and ending with complex processes in the chemical industry.