Creating complex components in the Engee physics modeling language

The Engee physical modeling language allows you not only to develop your own components, but also to combine different components into a single whole. Such components are called composite.

It's like a constructor, when there are parts (components) and our task is to connect them in the right order.

Why make composite components?

- "Packing" multiple components into one (as a subsystem in conventional modeling)

- Arrays of components

Example of a composite component

As an example of a composite component, consider a DC motor with an external shaft load.

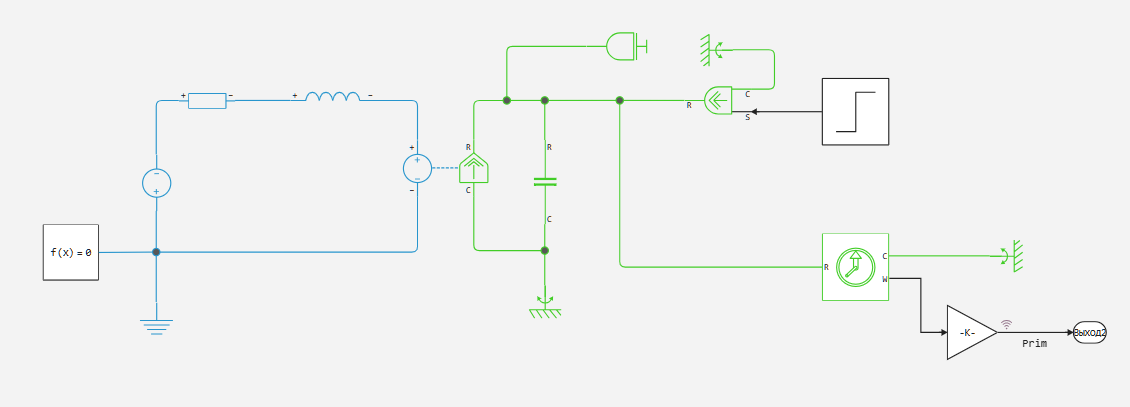

To make sure that the component was assembled correctly, let's take a reference implementation on primitives from the library of non-directional blocks.:

For testing, we will simulate the following scenario: in the first 0.1 seconds of operation, the engine runs without load on the shaft, and reaches maximum speed, and then a load occurs on the shaft.

Creating a composite component

Composite components are created in the same way as custom components using the Engee physics modeling language. Therefore, the component code must be contained in the *.ngpc file located along the Engee search path.

Let's look at the component code from the DCMotorComosite.ngpc file:

@engeemodel DCMotorComposite begin

@components begin

p = EngeePhysicalFoundation.Electrical.Pin(), [view = ("+", "left")]

n = EngeePhysicalFoundation.Electrical.Pin(), [view = ("-", "left")]

r = EngeePhysicalFoundation.Mechanical.Rotational.Flange(), [view = ("R", "right")]

c = EngeePhysicalFoundation.Mechanical.Rotational.Flange(), [view = ("C", "right")]

end

@parameters begin

rotor_resistance = 3.9, [unit="Ohm"]

rotor_inductance = 12e-6, [unit="H"]

motor_inertia = 0.01, [unit="g*cm^2"]

breakaway_torque = 0.02e-3, [unit="N*m"]

coulomb_torque = 0.02e-3, [unit="N*m"]

breakaway_velocity = 0.03347, [unit="rad/s"]

back_emf_constant = 0.072e-3*60/(2*pi), [unit="V/(rad/s)"]

viscous_coefficient = 0.0, [unit="N*m/(rad/s)"]

end

@components [gui = None] begin

rotorResistor = EngeePhysicalFoundation.Electrical.Elements.Resistor(R=default(rotor_resistance))

rotorInductor = EngeePhysicalFoundation.Electrical.Elements.Inductor(L=default(rotor_inductance))

motorInertia = EngeePhysicalFoundation.Mechanical.Rotational.Elements.Inertia(I=default(motor_inertia))

friction = EngeePhysicalFoundation.Mechanical.Rotational.Elements.Friction(w_breakaway=default(breakaway_velocity),T_breakaway=default(breakaway_torque),T_coulomb=default(coulomb_torque), viscous_coefficient=default(viscous_coefficient))

rotEMechConverter = EngeePhysicalFoundation.Electrical.Elements.RotationalConverter(k=default(back_emf_constant))

end

@equations begin

connect(p, rotorResistor.p)

connect(rotorResistor.n, rotorInductor.p)

connect(rotorInductor.n, rotEMechConverter.p)

connect(rotEMechConverter.n, n)

connect(rotEMechConverter.rod_flange, friction.rod_flange, motorInertia.flange, r)

connect(rotEMechConverter.case_flange, friction.case_flange, c)

end

end

Pay attention to how we create the sub-components - they are contained in the section @components. We initialize their parameters with values from the section @parameters

The assembly of the sub-components into a single component takes place in the section @equations using the function connect(). Please note that you can specify multiple connection ports at once!

Testing a composite component

Let's check the modeling results of our composite component relative to the same model, but using primitives.

demoroot = @__DIR__

engee.addpath(demoroot)

mdl = engee.open(joinpath(demoroot,"DCComposite.engee"))

sim_res = engee.run(mdl);

Let's plot the simulation results.:

using Plots

CustC = collect(sim_res["Cust"]);

Primitives = collect(sim_res["Prim"]);

plot(CustC.time,CustC.value, label = "Custom Component")

plot!(Primitives.time,Primitives.value, label = "The library of blocks")

plot!(legend=:outerbottom,legendcolumns=2)

Let's find the maximum absolute error:

err = CustC.value .- Primitives.value;

println("Maximum absolute error: $(maximum(err))")

The simulation results actually match, which means our component is working correctly!

Conclusions

The Engee physical modeling language is not just a language for writing custom components for 1-d modeling, but also a language for creating and describing complex physical systems. At the same time, the readability of the code was preserved, which is important for complex systems!