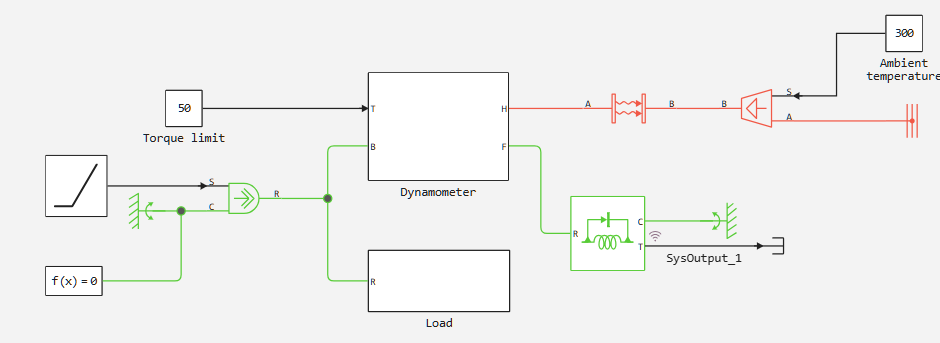

Dynamometer simulation

This project shows a dynamometer that counteracts the load from the primary engine. This primary engine is modeled as a torque source and can be an internal combustion engine, an electric drive, or a hydraulic motor. The dynamometer absorbs the input torque to the limit and allows the connected loads to rotate to achieve a torque exceeding this limit. The dynamometer itself is modeled using a fundamental friction clutch with static and dynamic constraints set according to the torque limit.

Simulation results

Open the model and run the simulation. Let's plot the moments and rotation speeds of the load.

m = engee.open(joinpath(@__DIR__,"dynamometer.engee"))

res = engee.run(m)

using Plots

RT = collect(res["SysOutput_1"])

T = collect(res["Torque Source.T"])

W = collect(res["Torque Source.delta_w"])

plot(RT.time,RT.value,title="Moment",ylabel="The moment, N*m",xlabel = "Time,from",label="Measured moment")

plot!(T.time,-T.value,label = "The source of the moment",legend=:outerbottomright)

p2 = plot(W.time,-W.value,title="Load rotation speed",label=false)

These graphs show the applied and resisting torques acting on the dynamometer. Please note that the dynamometer completely absorbs the torque before reaching its limit value. After that, it can continue to absorb it until the limit value is reached, but the additional torque from the primary motor will cause the attached load to rotate.